Prototyping is an essential phase for designing and delivering successful and well considered products to the market. Through the use of our in-house industry standard 3D printers, workshop and spray booth, our experienced model makers are able to explore, test and iterate concepts at increasing levels of realism throughout a project, from foam sketch models through to fully refined aesthetic prototypes with representative materials and finishes that can be used in user testing, crowdfunding, marketing and initial market feedback.

Prototyping

Rapid Prototyping

We offer a range of rapid prototyping solutions in-house, including both FDM and SLA 3D printers and high speed 5-axis CNC machining. 3D printing provides almost unlimited form freedom, doesn’t require tooling, and can produce parts with properties closely matching various materials made with traditional manufacturing methods. Access to these facilities allows the rapid production of prototypes and parts, quickly informing the shape, scale and functionality of your product, minimising risk and future expense.

Sketch Models

While a lot of our work has gone digital with 3D printed CAD models, we still strongly value the craftmanship of model-making. Foam is a versatile material used to make models quickly and efficiently. Our expert model-makers can cut and shape ideas, making them a great tool to rapidly assess and iterate the scale and form of a concept at an early stage before engaging in the fine detail. This stage is particularly useful for testing ergonomic factors and user interaction early on in the design process.

CNC Machining

Our CNC (Computer Numerical Control) machinery enables us to use 3D CAD data to carve and engrave complex shapes and geometry with a level of accuracy not possible by hand. With 5-axis indexed milling, the part can be rotated about on both the X and Y axis, and at multiple angles. This allows for complex positioning that can achieve sophisticated geometry. We can use our in-house CNC facilities to make prototypes, small production parts and prototype tooling quickly and cost effectively.

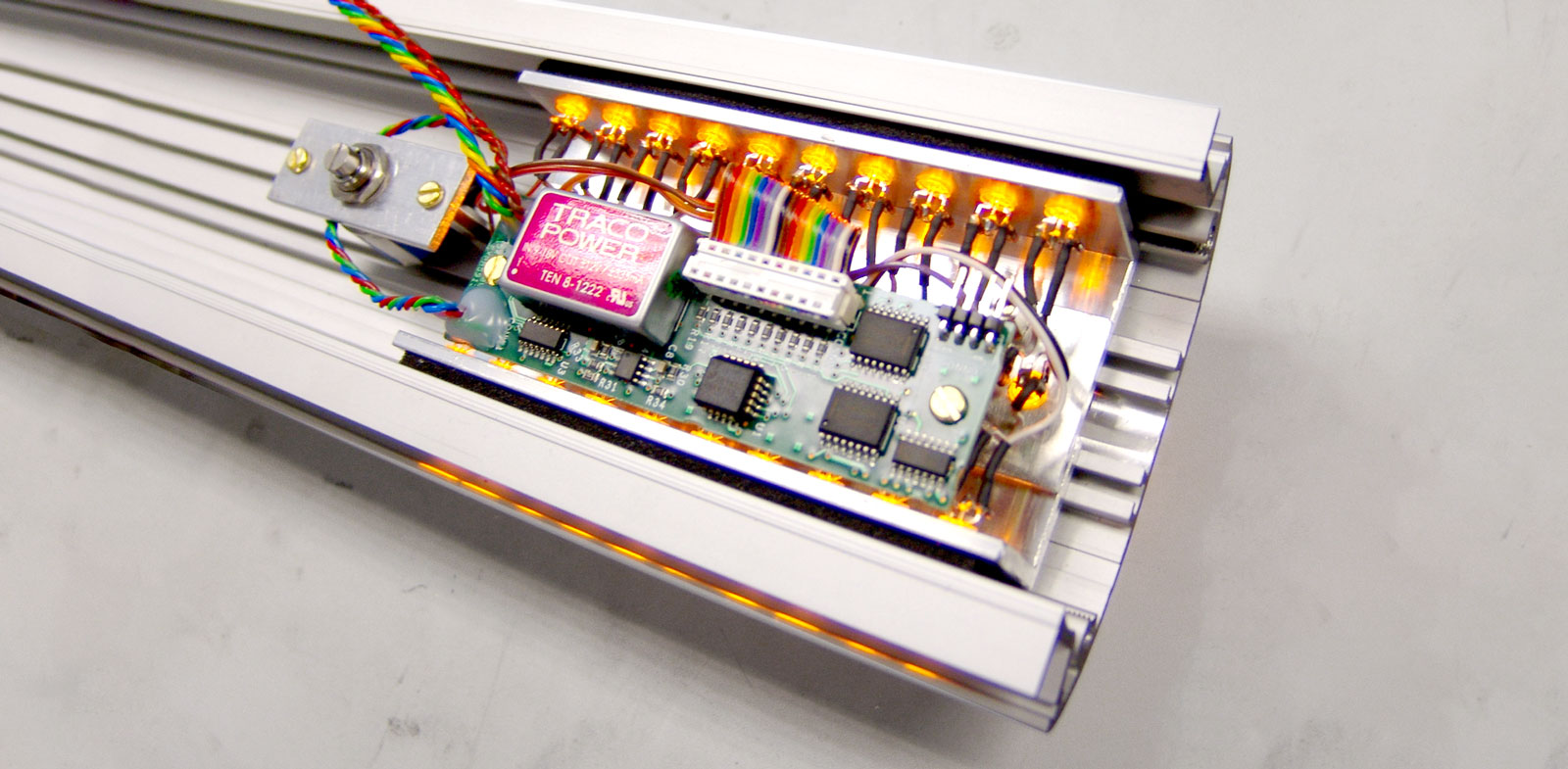

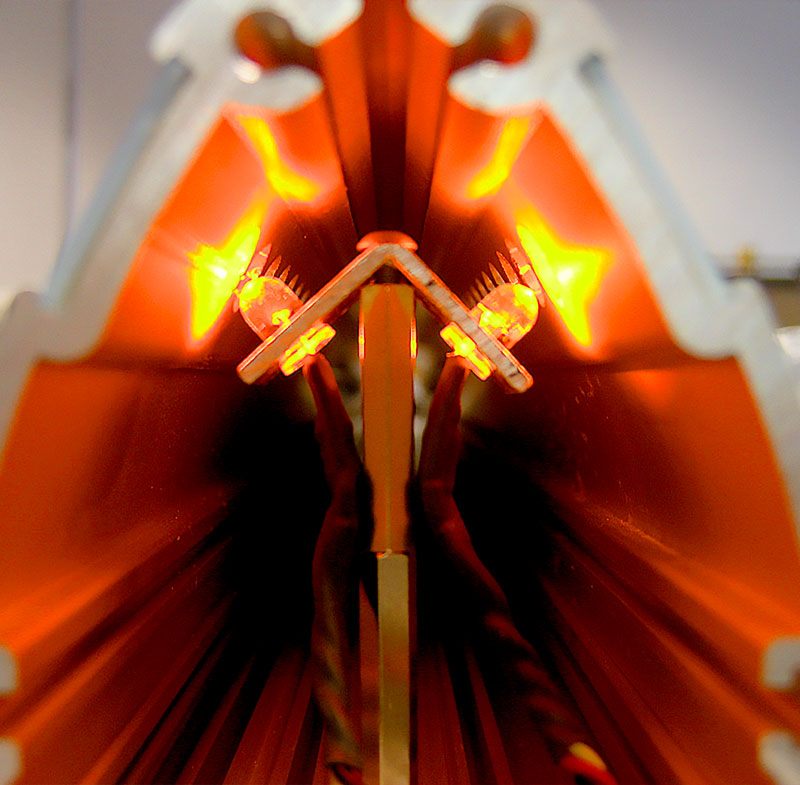

Electronic Prototyping

Similarly to physical prototyping, electronic prototyping assists in design iteration until the optimal design is achieved. Our in-house team has experience working with Arduino and other electronic prototyping techniques to allow the rapid testing of electronic principles. Working alongside our electronics partner, we are able to take these low fidelity prototypes and work with them to create high fidelity PCBs that can be taken through to production.